If you are responsible for delivering results in manufacturing, many times this is because of the large capital outlay that your facility represents. Management needs to deliver a return on that investment, and so manufacturing asset utilisation is a key concern for many people in the manufacturing industry: operators, engineers, supervisors, management, and executives.

If you would like to understand the best way to deliver great outcomes, read on!

Manufacturing assets typically include large or expensive pieces of equipment, but other assets such as warehouses, material, and labour could also be included.

The 5 key principles covered in this article are:

- Manufacturing assets don’t have to be fully utilised – only the bottlenecks

- Utilisation versus Efficiency – Busy versus Productive

- Efficiency vs Effectiveness – Are they making the right things?

- Overall Equipment Effectiveness targets – 40%, 60%, or 80%?

- Justifying capital expenditure for new assets – how to get your new equipment

Manufacturing assets don’t have to be fully utilised – only the bottlenecks.

Not every manufacturing asset should be fully utilised. Unless all of your operations and work centres are perfectly balanced, then there will be some areas that have less capacity and are more overloaded. Those areas are your bottlenecks.

It is possible that the bottleneck may change on any given day, due to changes in work mix, labour supply, recent breakdowns, or even scheduling and batching choices. The key skill is to determine those manufacturing assets that are genuinely critical bottlenecks and distinguish them from those that are short term or self-generated bottlenecks.

For each Value Stream, there will be exactly one bottleneck – the Constraint. Anyone who has read The Goal by Eliyahu Goldratt will be able to tell you why it’s only important that the bottleneck is fully utilised. (If you have not, add it to your reading list now!)

If the Constraint is fully utilised, then all of the other manufacturing assets and manufacturing assets are keeping pace with the Constraint. This means that maximum output of the system is being achieved, and if any non-Constraint were able to increase output then it would just sit as extra Work In Progress in front of the Constraint. No increase in output would be achieved!

So, it is critical that the bottleneck or Constraint assets are correctly identified and fully utilised. Everything else just has to keep up.

Utilisation versus Efficiency – Busy versus Productive

As we know, one of Peter Drucker’s famous quotes may be “what gets measured gets done”. If you are measuring asset utilisation, that is what you will get – working every possible hour, 100 percent utilisation.

Of course, the best way to increase utilisation is simply to slow the rate of output. This increases cost per unit, but if operators and management are being incentivised to deliver on a simple utilisation metric, that is exactly what will happen. See the heading “Gaming Your Metrics” in this article from the Harvard Business Review for several examples.

Simply measuring total output may also lead to undesirable outcomes, like excessive or unreported overtime, poor quality parts, skipped processes, safety locks bypassed, or maintenance neglected.

A better approach would be to include a metric based on efficiency – output generated per unit of input. Improving this metric reduces cost per unit. Tracking this metric alongside utilisation or output focuses operators and management on the correct behaviours and helps to drive genuine improvement rather than optimisation for a single outcome.

Efficiency vs Effectiveness – Are they making the right things?

A highly utilised and highly efficient machine (or other manufacturing asset) may be ticking along and rapidly generating a great volume of something that customers do not want, don’t want yet, or cannot be used before becoming out of date.

Those readers with exposure to Lean Thinking may recognise this as the waste of Overproduction, while fans of Peter Drucker may think it’s a reference to another of his famous quotes “Management is doing things right, Leadership is doing the right things”.

Whichever source of inspiration you choose, it’s critical for Leaders to make sure the manufacturing assets have been tasked with work that helps the organisation to achieve the goal of satisfying its customers. Management can then design and implement value streams to deliver that goal, including a useful set of measures to drive and assess performance.

Raffino Business Solutions can help with both Leadership and Management aspects of manufacturing asset utilisation – contact us today to discuss.

Overall Equipment Effectiveness targets – 40%, 60%, or 80%?

Once you have identified the bottleneck or Constraint, and made sure that it can be both Efficient and Effective, then you are well placed to benefit from the field of Overall Equipment Effectiveness.

In fact, you will have already considered the following questions:

- What is the maximum possible output from this manufacturing asset?

- What output are we achieving, compared to that?

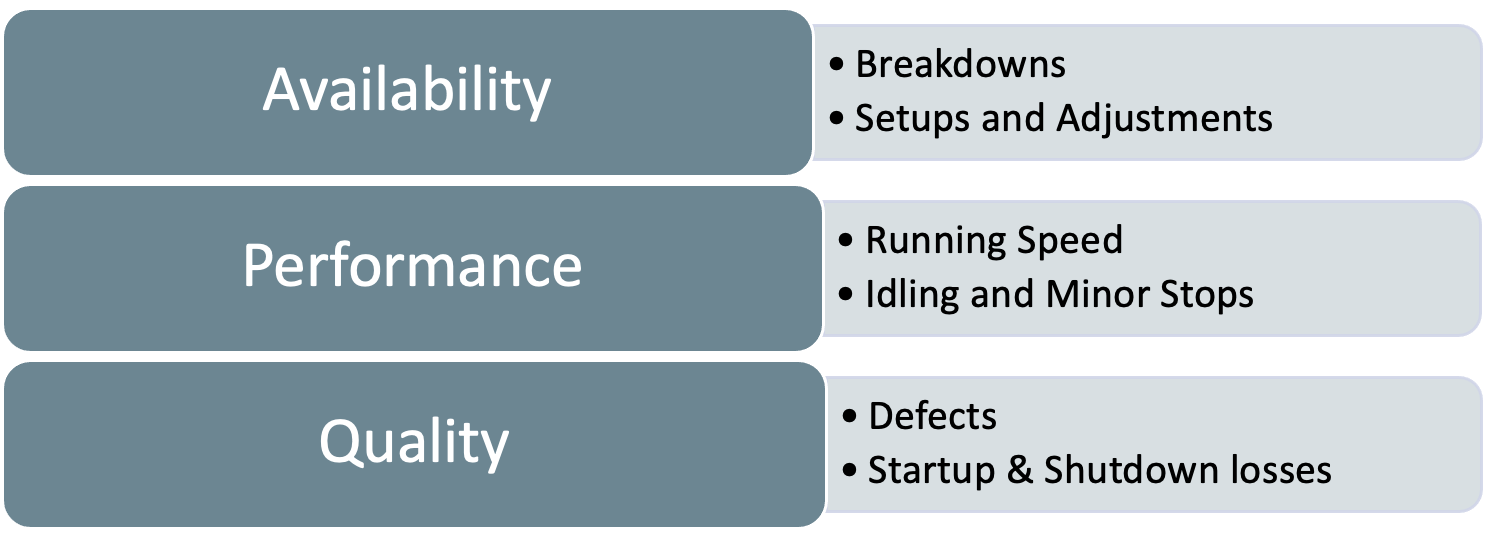

The discipline of Overall Equipment Effectiveness adds structure to that thought process, by breaking losses into categories of Availability, Performance and Quality. This is further broken down into six categories of losses, which between them capture every possible cause of lost output. Recording and analysis of this data can provide opportunities for improvement, to maximise output.

An example of the categories is shown below:

A reasonable question to ask at this stage is “What’s a good target for OEE? What do companies typically achieve?”, and the answer may surprise you.

Typical companies who are just starting to focus on manufacturing asset utilisation often achieve OEE of around 40%. 60% is considered good, and 85% is considered World Class. That means that you are probably achieving less than half of the possible output for your most critical manufacturing assets.

For the ambitious readers among you, the 85% OEE target is made up of:

- 90% Availability – 10% reserved for changeovers, and zero breakdowns,

- 95% Performance – the machine is running at design speed nearly always, and

- 9% Quality – nearly perfect quality with very few rejects.

Multiplying these three factors together gives 85.4% OEE, which is an excellent result.

Justifying capital expenditure for new assets – how to get your new equipment

Often, new equipment or other manufacturing assets are necessary to meet output goals. However, reviewing this article so far, it’s quite common that the board and management of companies feel that there is a lot of potential performance which is currently unrealised. This makes them reluctant to approve further expenditure, especially given the likelihood that the proposed solution will also under-perform!

This state of affairs often results in a demoralising cycle: Capex request, denial by management, underperformance, Capex approval, unfulfilled promises, and increased difficulty for future capital expenditure.

Consider instead, an alternative scenario! Follow the steps outlined in this article:

- Focus on the bottlenecks. This reduces workload and increases results.

- Ensure that the key manufacturing assets are both efficient, and effective. Making what the customer wants and lowering cost per unit.

- Overall Equipment Effectiveness is measured, known widely, and is high. The assets are highly productive, and you can prove it.

High OEE means that there’s little more capacity to squeeze out of the asset. High OEE means that management can be confident a new asset will also be professionally managed and highly productive. A Lean system and business strategy that ensure assets are both effective and efficient delivers strong profits, improving access to capital. The constrain focus ensures that capital is deployed in the right place, delivering good return on investment, and the demoralising cycle is broken.